World’s first IGBT-based green EAF is up and running

Date:2022/2/25 Source: CISDI

The groundbreaking green energy CISDI-AutoARCTM is operating successfully at Pangang Changcheng Special Steel in Sichuan Province.

This super-efficient and green electric arc furnace is the world’s first for applying an IGBT-based flexible DC power supply. Its melting operation at Changcheng Special Steel is stable and hitting smooth tapping targets.

It sets an industry precedent for green, efficient and cost-effective Mini-mill production.

● CISDI-AutoARCTM is a world-class green, efficient product which meets low-carbon and energy-conservation production requirements

The electric arc furnace is a key element of the Mini-mill process, which uses two thirds less energy and produces two thirds fewer carbon emissions than an integrated process with BF-BOF at its core.

The Mini-mill has become a critical route for transforming steel processes to green, sustainable levels.

Researched and developed by CISDI, AutoARC has achieved major breakthroughs in critical process, equipment and control expertise while providing total solutions to full-scrap-charged electric arc furnace melting, traditionally a high and inefficient energy-consuming process.

CISDI’s green, efficient electric arc furnace has been started up and put through one heat at Pangang Changcheng Special Steel.

CISDI-AutoARCTM, operating stably at the plant

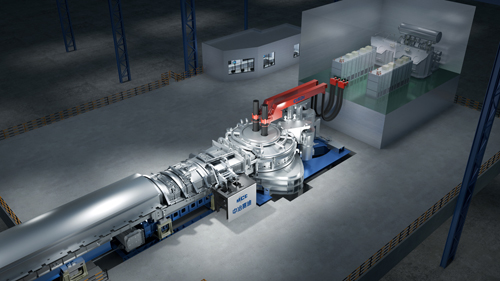

A model of the CISDI-AutoARCTM

● IGBT enables CISDI-AutoARCTM to operate with higher efficiency

CISDI’s super EAF is applied. It features innovative insulated gate bipolar transistor based flexible DC power supply, dual cathodes plus air-cooled, feeler-pin bottom anode equipment and control system.

Melting efficiency is increased, resulting in a power supply output response speed of 0.1 millisecond, a grid-side power factor of less than 0.95, a voltage and current fluctuation ratio of lower than 3 per cent, and an entire power supply loss controlled to within 3 per cent.

The IGBT flexible DC power supply expertise has solved the following problems experienced with existing EAF systems:

✔ Large impact on the grid

✔ Output voltage and poor current regulation and weak resistance against impact

✔ Failure to recover busbar’s capacitance

✔ Inadequate protection for power supply over-voltage and over-current.

CISDI engineers implement ex-works testing for the installation of the IGBT unit at an EAF

The air-cooled, feeler-pin bottom anode, to be installed at an EAF

● The upgraded super electric arc furnace is showcasing remarkable KPIs

The conventional 40-tonne AC EAF has been transformed to a cost-effective, green production unit.

The benefits:

✔ Reducing tap-to-tap cycle time by 15 minutes per heat

✔ Reducing electricity consumption by around 50kWH per tonne of liquid steel

✔ Decreasing electrode consumption by 1.7 kilograms per tonne of liquid steel

✔ Reducing carbon dioxide emissions by over 40 kilograms per tonne of liquid steel.

The successful application at Changcheng Special Steel will advance China’s own EAF tech to the levels achieved by its world-class partners.

CISDI will continue to focus on building full-process digital, smart steelmaking. Its Mini-mill total solutions, featuring high efficiency, low consumption, eco-friendly and intelligent operation, will be a driving force in China’s pursuit of ever-higher standards for steel production.