CISDI’s first heavy rail universal mill rolls into action - a major step for China’s rail network

Date:2022/2/25 Source: CISDI

China can now manufacture the rail products it needs to create the country’s high-speed railway lines, rather than relying on imports.

Yongyang Special Steel in China’s Hebei Province is now able to produce heavy rail sections, thanks to a new line recently created with CISDI’s expertise.

The line is the first of its kind in China and is operating successfully.

CISDI provided all critical process, equipment and control tech.

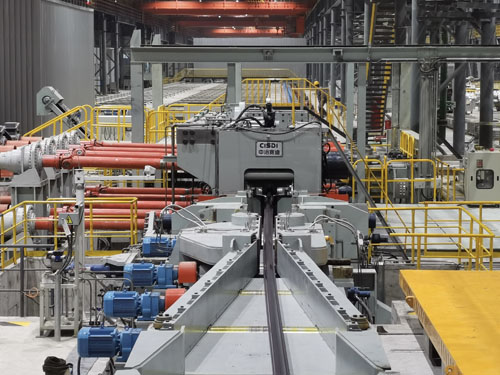

CISDI’s equipment, successfully started up at Yongyang Special Steel

The line applies CISDI’s two-stand reversing Breakdown Mill and three-stand reversing Universal Mill.

Main products produced are premium rails and beams to China’s national standard, European and British rail standards and crane rail standard, mineral sections, H sections, I beams, channels and angles.

Total production capacity is expected to be 900,000 tonnes a year.

The CISDI-supplied UMCD Universal Mill, installed at Yongyang Special Steel

The BDCD Breakdown Mill, delivered by CISDI to Yongyang Special Steel, is operating smoothly

Yongyang’s heavy rail production line features world-class technology and equipment levels, thanks to CISDI-developed, designed and manufactured critical process, equipment and control systems. Features include:

✔ Groove design for various complicated product cross sections and relevant screw-down process

✔ New-generation BDCD Breakdown Mill

✔ Hydraulic, closed housing UMCD Universal Mill

✔ RSCD standardised portal horizontal straightener and cantilever vertical straightener

✔ TCS-based intelligent roll gap control for the Universal Mill

✔ HPC automatic hydraulic position control

✔ AGC automatic roll gap control

✔ Automated, unmanned rolling control for the main rolling line.

The straightener in operation at Yongyang Special Steel

The hot-tested bar was a shaped mineral steel section – U section (U29), featuring an irregular shape and requiring a complicated process.

The first rolled U section resulted in qualified section dimension and surface quality.

All process, equipment and electric and automation systems performed perfectly, so hot testing was followed by trial production.

Fact File:

Yongyang Special Steel is located in Handan City in China’s Hebei Province. It produces special steels sections and quality steels:

Special sections – light rail, heavy rail, mineral section, crane rail and U-shaped section

Special steels – flat section for automobile leaf springs, high-strength hot-rolled flat for the automobile sector, tubular stock for medium and high-pressure boilers and petroleum casing tubular stock.

The company’s first Chinese-made light rail rolling line went operational in 2020 with a Universal Mill at its core. CISDI supplied critical process, equipment and control.