CISDI successfully rebuilds TISCO’s ageing caster 3

Date:2019/5/20 Source: CISDI

CISDI

successfully rebuilds TISCO’s ageing caster 3

CISDI has

successfully rebuilt TISCO’s caster 3.

The 16-year-old

combined square bloom and slab caster was not functioning correctly. Its

secondary cooling control system had failed to apply the cooling model to

control slab edge water flow. An unreliable regulating valve could not regulate

water stably in the event of a low flow.

CISDI has

replaced them with its unique secondary cooling dynamic control model.

Optimised

design has also been implemented to solve a problem which was resulting in a

serious blocking of the caster’s nozzles, and to improve the arrangement of the

secondary cooling loops, instruments and spraying.

TISCO’s caster

3 rebuild is shining example of how CISDI’s secondary cooling dynamic control

model can dramatically improve stainless steel casting, a sector which has been

exclusively-dominated by suppliers outside of China.

After the

rebuilds, on the first run, ferritic stainless steel 0Cr13R was cast

successfully with a cross section dimension of 200mm x 1,235mm. A uniform

distribution of surface temperature and a stable control of width were

achieved. The first casting speed ranged from 0.9 to 1.05 metres a minute.

Analysis showed

the slab’s central segregation had reached Mannesmann 1 level, and its equiaxed

crystal ratio had surpassed 60 per cent.

Since the first

cast, slab grades 0Cr13R, 2Cr13, 430, 409, 20Mn23AlV, 441, 443 and 308 have

been achieved.

TISCO’s caster 3 ejects its first stainless

steel slab for the first cast

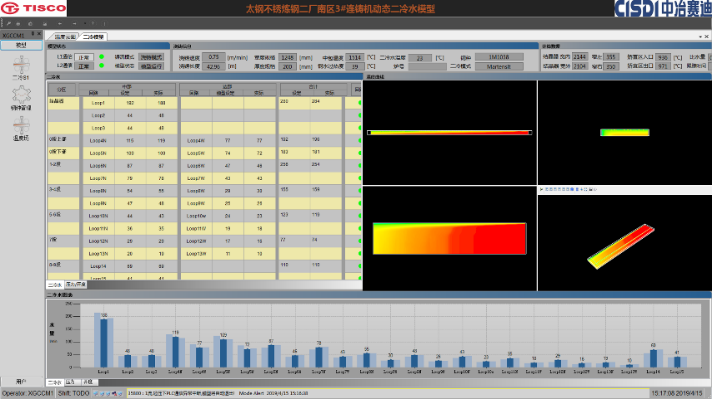

The

benefits of CISDI’s 3D secondary cooling dynamic control model

The model ensures optimal strand temperature and

high quality slab.

It automatically matches steel grades with

proper control strategy.

Secondary cooling water flow and compressed air

flow can be real-time adjusted to strand temperature.

From any duty position, operators are able to

read strand’s real-time temperature status and make optimisation decisions.

A screen shot of CISDI’s model performing hot

strand tracking