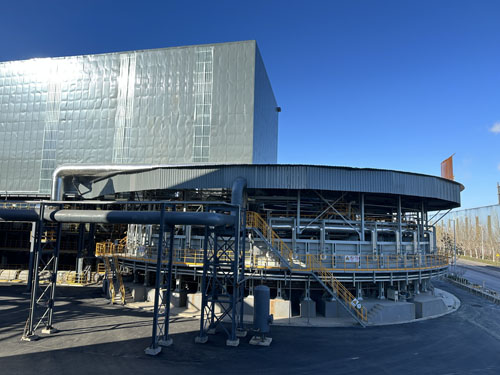

Hebei Jinxi’s new rotary hearth furnace is in pilot production

Date:2025/3/21 Source: CISDI

CISDI Thermal and Environmental Engineering Co has built a new rotary hearth furnace at Jinxi New Materials Technology Co in China’s Hebei Province, to an EPC mode.

The RHF is now in pilot production after successful hot testing. The projected annual treatment capacity is 250,000 tonnes.

A cold briquetting line supports the furnace’s downstream processing, which features an annual capacity of 60,000 tonnes.

Jinxi’s Fe- and Zn-bearing solid wastes are now being converted to resources in a highly efficient way.

CISDI Thermal’s tech cluster, which has Fe- and Zn-bearing solid waste-to-energy and eco-friendly, efficient treatment at its core, is applied to the furnace and briquetting projects.

It fully recovers zinc element from dusts harnessed by blast furnace ironmaking’s bag filter and gravity dust catcher systems, and also from the BOF’s secondary and tertiary dust collection systems. At the same time, BOF’s primary dust collection system is treated.

Recovered zinc is then recycled into metallised pellets containing a high degree of iron element.

The project also incorporates CISDI Thermal’s smart management and control platform. Design data and production information is integrated on the platform, enabling real-time, efficient connections of the computing, data and expert resources.

The platform has aided full-process, all-factor smart production decision-making.

At its end-of-year meeting, Jinxi New Materials Technology Co presented an Outstanding Contribution Award to CISDI Thermal in recognition of its project management and onsite professionalism.

The rotary hearth furnace at Jinxi New Materials Tech Co is now in pilot production with load

CISDI Thermal’s smart management and control platform has taken Jinxi RHF to smart operation